How do changes of the environmental temperature affect the manufacturing accuracy? How can you test these effects from an early stage of the design?

If these questions pop into your mind, then you are at the right place. You are ready to start exploring the fascinating world of thermo-mechanical simulations. Since we released MORe 2.0 Uors in 2018, we have extended MORe to include thermo-mechanical effects. In this blog post, you will see an application example that evaluates the effect of changes of air temperature on the performance of a machine tool.

Model setup

The RMT MORe model is used. It is a 3-axis machine tool model with linear direct drives in X-, Y- and Z-direction. This is the model we use in our course to teach you the capabilities of MORe.

Effect of a sudden drop of the air temperature

Let’s take a look into the analysis of a sudden change of the environmental temperature as it appears often in machine halls in situations like:

- Opening the doors of the workshop.

- Turning on and off the air conditioning system (for energy saving reasons).

We have a machine hall at constant temperature of 20°C. Due to the loading and unloading of trucks, the door of the machine hall remains open for 12h. This leads to a drop of the temperature inside the workshop from 20°C to 16°C. Additionally, the machine tool has an active cooling system for the spindle and the direct drives. The set temperature of the cooling system is 20°C and remains constant throughout the day.

How can we study this case using MORe? MORe offers the possibility to perform transient thermo-mechanical analyses. You can define the environmental temperature as the input of the transient simulation and thanks to the cutting-edge model order reduction methods, the simulation time is short without compromising the accuracy of the results.

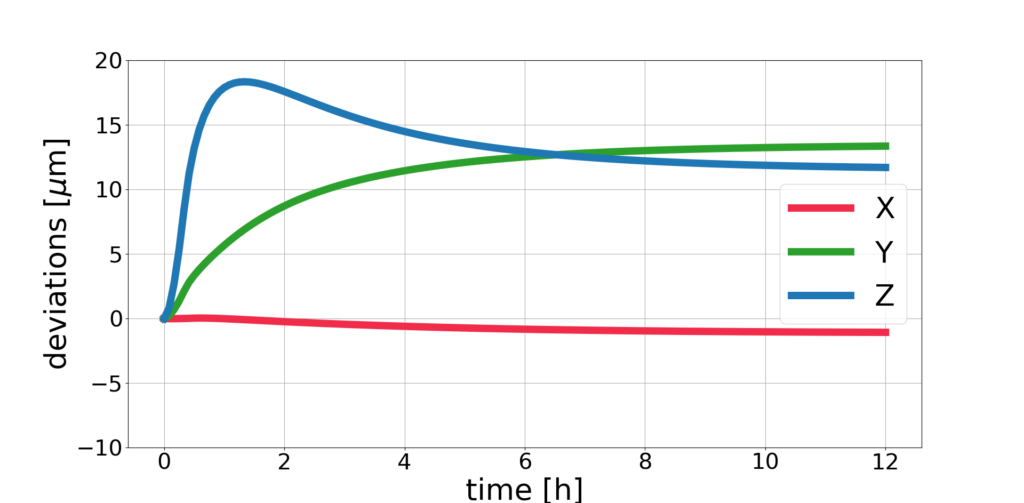

The first figure shows the simulated thermal errors between the tool center point (TCP) and the workpiece in X-, Y-, and Z-direction due to the drop of the environmental temperature. We see an interesting effect in Z-direction. The maximum value of the displacements in Z-direction occurs before the first 2 hours of the simulation. Some components respond faster than others to changes in the environmental temperature, resulting in this behavior of the thermal errors in Z-direction.

How can you understand better the influence of the air temperature on your machine tool? We have a full-featured postprocessor that will allow you to get an in-depth knowledge about the machine tool design. You can visualize the temperature field and deformation of the structure. For the sudden drop of the air temperature, we see that the spindle cooling leads to a temperature gradient in the Z-axis. This temperature gradient results in a structural deformation, as shown in the animation.

What about other positions in the working space?

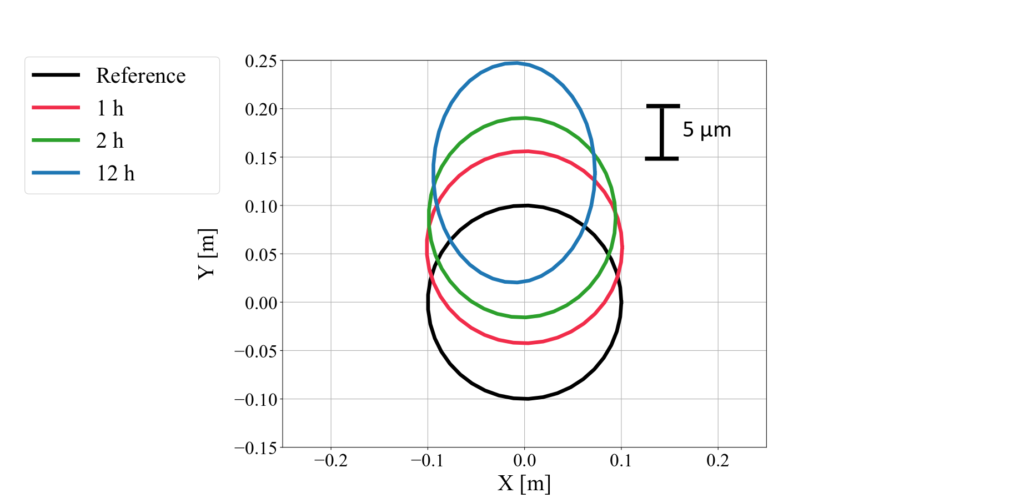

The previous example shows us the thermal errors of the machine tool due to the drop of the environmental temperature. We show displacements of the TCP in X-, Y-, and Z-direction at one axis position. How are the thermal errors at other position of the linear axes? MORe is the perfect tool to answer this question efficiently. We implemented moving interfaces to evaluate the mechanical deformation of the machine tool at different positions of the machine tool axes.

In order to visualize the effects of the thermal errors at different positions of the axes, we create a circular trajectory. The circular trajectory involves the movement of the X- and Y-axis with a diameter of 0.2 m. We illustrate the original trajectory and the trajectory after 1 h, 2 h, and 12 h of the temperature drop. We can see that the center of the trajectory moves mainly in Y-direction. Additionally, we see that the shape of the trajectory varies. This will lead to a form error in our manufactured part.

Take-home message

In this blog post, we introduced a first case study on evaluating the thermal design of a machine tool. We learnt that the environmental temperature fluctuations have a direct impact on the precision of the machine tool. Furthermore, the thermal errors depend on the position of the axes.

Do you want to learn more about thermal simulation of machine tools? Check out our latest release and unveil a world of improvement potential for the precision of your machine tool design.