Software taylored for machine tool simulation

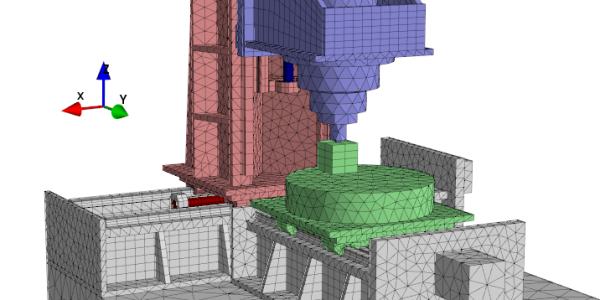

MORe is a comprehensive software package that allows an efficient and straightforward workflow and features a multitude of analysis options. It has been developed with the specific properties of machine tools and the questions arising during machine tool development in mind. MORe enables you to create a virtual prototype of your machine tool, which can be used for design, control, or trouble-shooting purposes.

More efficient, more accurate

Efficient workflow

Straightforward workflow, as little task repetitions as possible

Efficient calculation

Efficient algorithms for model reduction and modelling of moving interfaces on flexible bodies

Efficient analysis

Easy-to-use and comprehensive analysis tools for the analysis of machine tools in the whole working space

Accurate results

Novel model order reduction method featuring an a-priori error estimation for a specifiable frequency range

Rely on well-established tools -

enhance with cutting-edge methods

User interface

MORe offers an intuitive GUI which allows to create a new model with ease.

Using the Mayavi package for 3D visualisation, MORe offers state-of-the-art visualisation and is easily extendable.

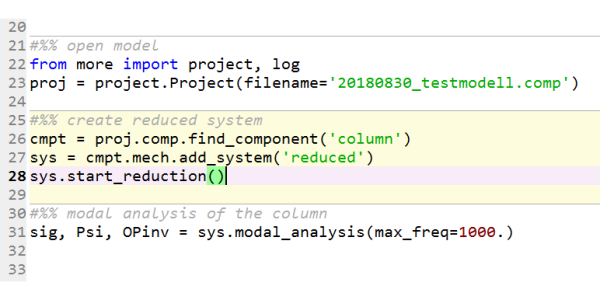

MORe is written in Python and offers a clean API, and can thus be used from the console or be scripted. A mixed workflow with tasks performed with the GUI and repetitive tasks automatised using scripts lets you handle vast modelling problems efficiently.

Exporting a component from ANSYS involves nothing more than running one macro.

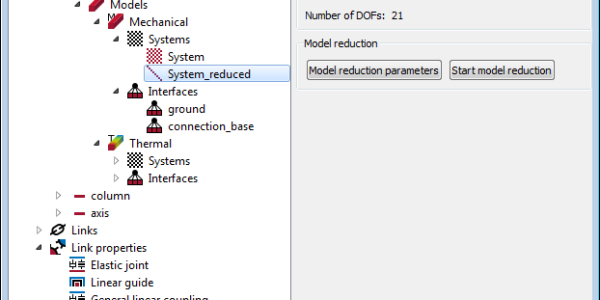

Mechanical model

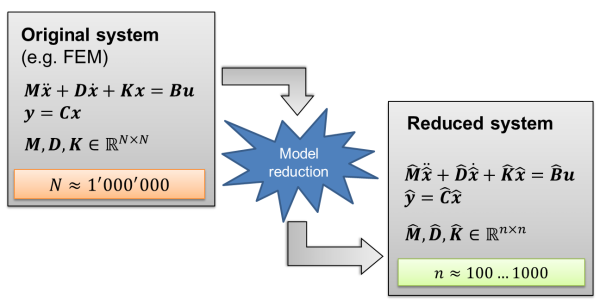

- Cutting-edge model order reduction using Krylov and modal subspaces

- Error bound in a specified frequency range

- Exact matching of the static behaviour

- Exact matching of eigenmodes

- 6-DOF force application and displacement evaluation

- Stationary interfaces (e.g. bearings, TCP, linear guide carriages, process forces)

- Moving interfaces (e.g. linear guides rails, ballscrew spindles, linear motors, and scales)

- Local coordinate systems

- Links, defining the couplings and actio-reactio-relations between interfaces

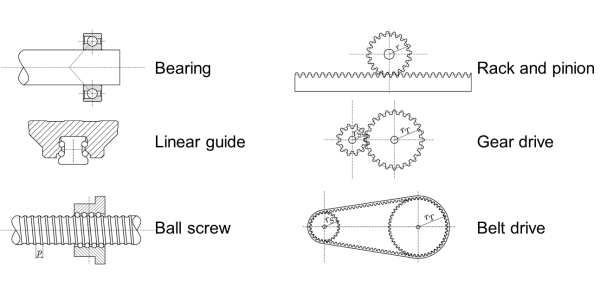

- Link properties for mechanical components:

- bearings

- linear guides

- gear drives

- belt drives

- ballscrew drives

- rack and pinion drives

- general flexible joints

- Non-linear link properties:

- Kinetic friction

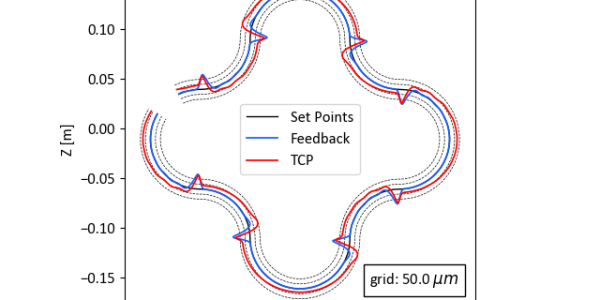

Versatile predefined analysis types can be performed for any axis configuration (position, orientation)

- Static analysis

- Modal analysis

- Frequency response analysis

- Transient analysis

- Result representation as data plots and tables

- Animation of the deformed structure:

- oscillation shape animation

- scaled deformation

- scaled error for transient simulation results

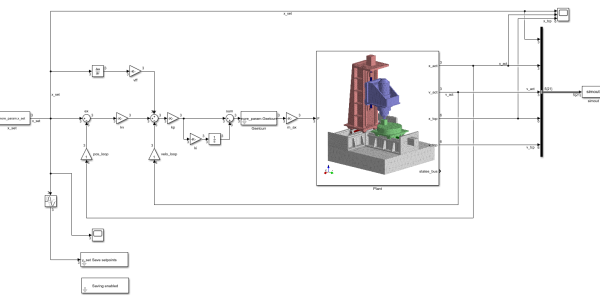

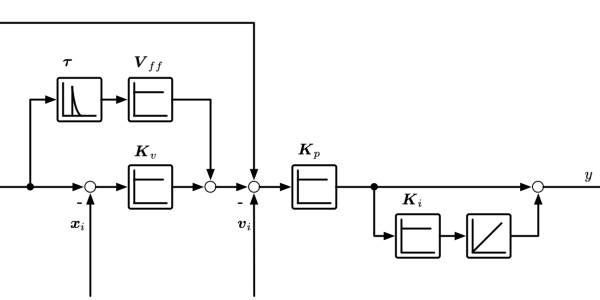

Mechatronic model

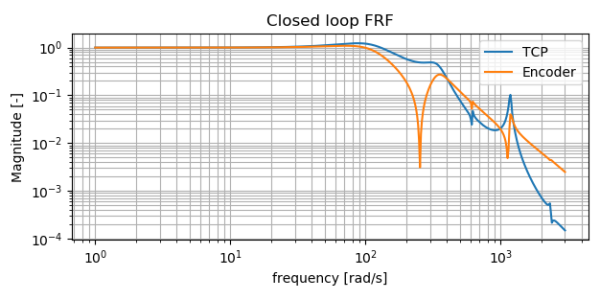

- Standard cascaded loop controllers are built in

- Modify controller gains with ease

- A series of predefined current command filters for each controller

- Low-pass

- High-pass

- Band-pass

- Band-rejection

- Bi-Quad

- All mechanical analyses can be used with the closed-loop mechatronic model

- Static analysis

- Modal analysis

- Frequency response analysis

- Transient analysis

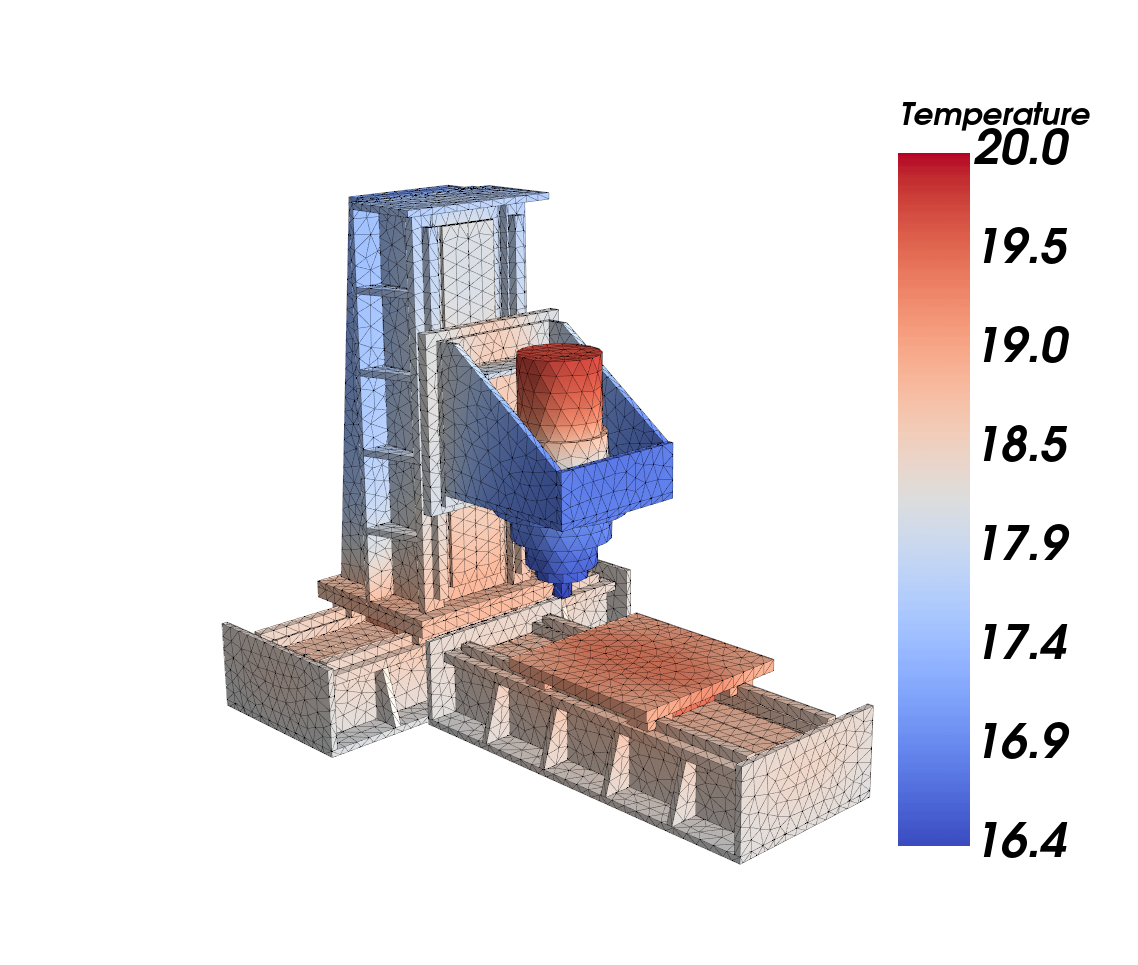

Thermal model

- Cutting-edge model order reduction using Krylov and modal subspaces

- Error bound in a specified frequency range

- Local heat flux interfaces (e.g. heat sources such as motors)

- Distributed convective interfaces (e.g. convection on surfaces)

- Links, defining the heat exchange between interfaces

- Link properties for thermal conductivity and convection

- Steady-state thermal analysis

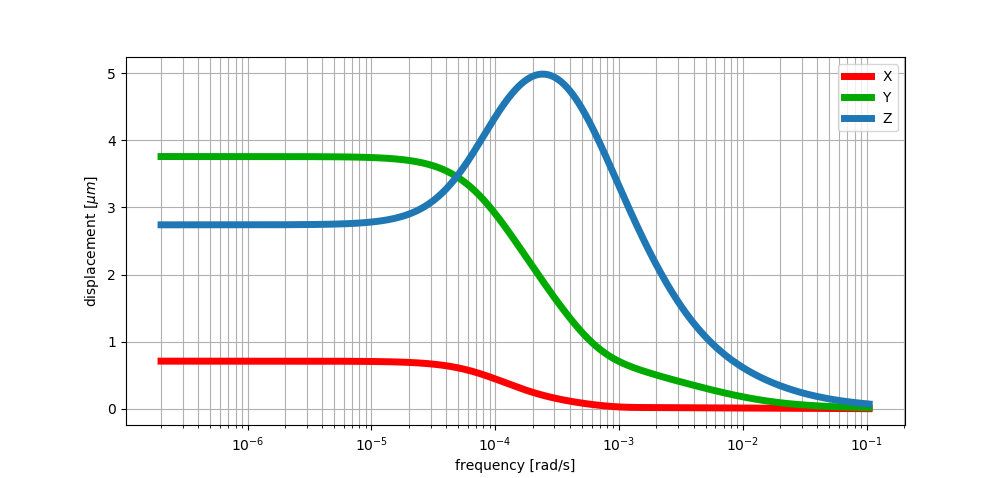

- Frequency response

- Transient thermal analysis

- Result representation as data plots and tables

- Visualisation of structure temperature by means of contour plots

Thermo-mechanical model

- Reduced mechanical models

- compatible with thermal loads

- compatible with static mechanical loads

- Seamless integration of thermal and mechanical loads for thermo-mechanical analysis

- temperature from thermal analysis results as thermal loads

- uniform temperature as load

- static loads (forces, torques, or acceleration)

MATLAB toolbox

- Load MORe projects into MATLAB workspace

- Modify model parameters (e.g. stiffness values, axis positions)

- Access model properties like system matrices or interface matrices

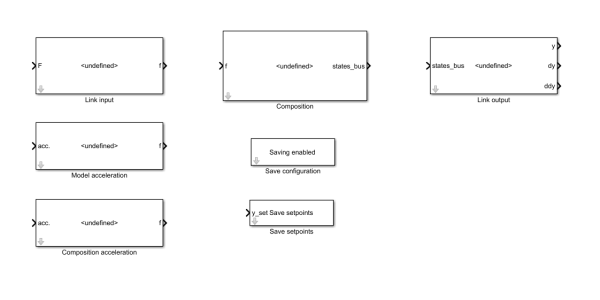

- One block represents the mechanical structure

- Blocks for in- and outputs (selection via drop-down menu)

- Blocks for automatic result saving

- Combine with standard Simulink and Simscape blocks

- Predefined methods for linearisation, frequency response, and modal analysis of simulink models

- Transient simulation of linear or nonlinear models

- Loading of simulation results into MORe

- Animation of results (frequency resoponse, modal analysis, transient simulation, custom results)